The operation of any business hinges on the procurement of essential goods and services from third party vendors. While there are two participants in a procurement process – the buyer and the seller, it is the act of procurement by the buyer that is referred to as the procurement process. Procurement is critical to the buyer’s business because it decides the quality of the goods/services to be used by the business, and the cost benefits associated with it.

Let us see what the procurement process is and why digitizing the process offers advantages.

What is a procurement process?

The procurement process, also known as procurement management, is the umbrella term for the steps by which an organization acquires goods/services required for its operation. Procurement management differs across businesses according to the needs, scale, and operations of the organization.

The procurement process could include purchase planning, determination of standards, research into vendors, selection of vendors, price negotiation, financing, ordering, receipt, and inventory control. The process may involve multiple departments such as the purchase department, finance department, etc. Large businesses often have a centralized procurement department with its own employees and procedures.

A well-laid and managed procurement process saves costs, aids compliance, and avoids delays and errors that could be detrimental to the company’s bottom-line. In recent times, procurement process flows are also being used by businesses to achieve non-financial goals such as sustainability and environmental compliance.

Looking to automate your manual AP Processes? Book a 30-min live demo to see how Nanonets can help your team implement end-to-end AP automation.

Difference between procurement and purchase

While procurement appears to be the same as purchasing, they are different in the business context.

- Purchasing is a transactional function that involves sourcing and acquiring products and services.

- Procurement is a strategic process that involves researching the needs of the company, scouting for vendors/sources, negotiating, and planning the purchase and follow-up processes.

In other words, purchasing is the straightforward process of buying the goods/services from vendors, while procurement involves steps taken before, during and after the purchase process and handles all steps in the Procure-to-Pay cycle. Thus, purchasing may be considered a subset of the procurement process.

Types of procurement

There are three types of procurement for any business:

- Direct procurement: This is the acquisition of goods, materials, and/or services for manufacturing purposes. Examples are machinery, raw materials, chemicals, etc. These are usually stock materials that are used to drive the output of the business.

- Indirect procurement: This involves acquisition of products and services that are used internally by the company. Examples are utilities, stationery, travel and such other consumables and perishables. These are things that the company needs for its daily operations.

- Services procurement: As the name suggests, this involves procuring workforce, services and consultancies. This may also include professional services, outsourcing, software subscriptions, etc.

Steps in the procurement process

The procurement process depends on factors such as company size, business model, location, structure of the business, budget, human resources, etc. Despite differences between the actual steps, all procurement processes are made of three essential units – rules, participants, and record-keeping.

Rules are the conditions that are unique to the company that must be followed when ordering, obtaining, and paying for goods/services needed. The more the rules, the more complex the procurement process.

Participants are the personnel from the company that have a stake in the procurement of the product or service and have a specific responsibility in the process of procurement. The higher the value of the product/service to be procured, the larger is the circle of stakeholders in the procurement cycle.

Record-keeping: Meticulous and accurate record-keeping is essential for a smooth procurement process. Record-keeping is also essential for reference, auditing, and budgeting purposes.

Some typical steps that are seen in a procure-to-pay cycle are as follows:

- Identification of the internal need: When a department or business unit requires some product or service for its functioning, the procurement department is brought into the loop. If the same product/service is required by another business unit, the requirements of both departments are consolidated for better costing and management.

- Identification and evaluation of the vendor: Depending on the scale of operations and the value of the product/service required, the vendor may be chosen by a simple web-search or through complicated RFP/RFI/Tender processes. Once a set of vendors has been identified, they are compared for quality, price, reliability, customer service and other criteria that the company deems important. The procurement department selects the best vendor or vendors after this comparison.

- Vendor negotiations: The contracting process may be said to commence at this point. The contract may simply be a call for quotation, issuing purchase orders and getting the item. On the other hand, it may also involve back-and-forth negotiations to fix the quality, quantity and timelines for the purchase.

- Generation and approval of purchase requisition: This step is taken in large companies, wherein, the department or unit that requires the product/service, draws up the purchase requisition. This is an inter- or intra- departmental document/form that defines the need, the cost associated with that need, and other pertinent information. The requisition is reviewed and approved by the department head or the entity responsible for paying for the product/service.

- Generation and issue of the purchase order: Once a purchase requisition for goods/services has been approved by the appropriate department(s), the order must be placed with the vendor. A purchase order specifies the quality and quantity of the goods/service needed, the time frame of the order and the price/costs involved. The purchase order is a legally binding document between the company and the vendor.

- Receiving the invoice: In response to the PO raised by the business, the vendor raises an invoice with a list of the ordered items along with prices and payment due dates. In accordance with the negotiated terms, the payment is made by the business before or after the delivery of the product.

- Product receipt: The product/service is supplied by the vendor to the business. The business performs a three-way-matching of the PO, invoice and the receipt, to ensure that the right product/service has been delivered at the stipulated time, and at the right price. The vendor is notified in case of any discrepancies for further action.

Set up touchless AP workflows and streamline the Accounts Payable process in seconds. Book a 30-min live demo now.

Challenges in the procurement management process

The procurement process deals with a number of steps as listed above, and with increasing scale of operations, the process could get even more complex and fragmented. Some specific challenges that would then arise in the procurement management process are:

- Breakdown of strategy: Without cohesion among the various steps and stakeholders, what is supposed to be a strategic process can become a patchwork activity, which can have serious outcomes on the operations of the company and eventually the bottom-line.

- Vendor management issues: Fragmented procurement management would make it difficult to rope in and retain reliable vendors that deliver quality goods and services on time. Poor procurement management results in poor vendor management, which in turn results in the procurement team wasting valuable time firefighting vendor problems.

- Delays: Mismanagement or poor management of the procurement process can result in delays in acquiring products and services that are important for the functioning of the company. Inefficiencies in the procurement processes can result in slowdowns, missed project deadlines and losses to the company.

- Inventory problems: Poor procurement management can create over- or under-supply of inventory and may even result in commitments not being met on time.

- Data insecurity: A poor procurement process can result in poor record keeping and unreliable data, which can translate to bad decisions in future operations. Some procurement risks that can result from data insecurity are overstatement or understatement of the need, unrealistic timelines and schedules, and poor budgeting.

- Maverick purchasing: A fragmented and mismanaged procurement process can result in employees bypassing set procedures while making purchases. This may result in budgeting issues and deviation from compliance standards.

- Human resource management: Poor procurement management could result in extra work for employees in chasing down paperwork and organizing inventory/budget. This results in loss of time and human effort that could be spent on more profitable pursuits.

Book this 30-min live demo to make this the last time that you’ll ever have to manually key in data from invoices or receipts into ERP software.

Automation of procurement management

As a company grows in size and operations, manual procurement processes are not capable of meeting the growing demands. Digitization and automation of the procurement process flow can help overcome many of the challenges described above.

Some specific advantages of automating the procurement management process are:

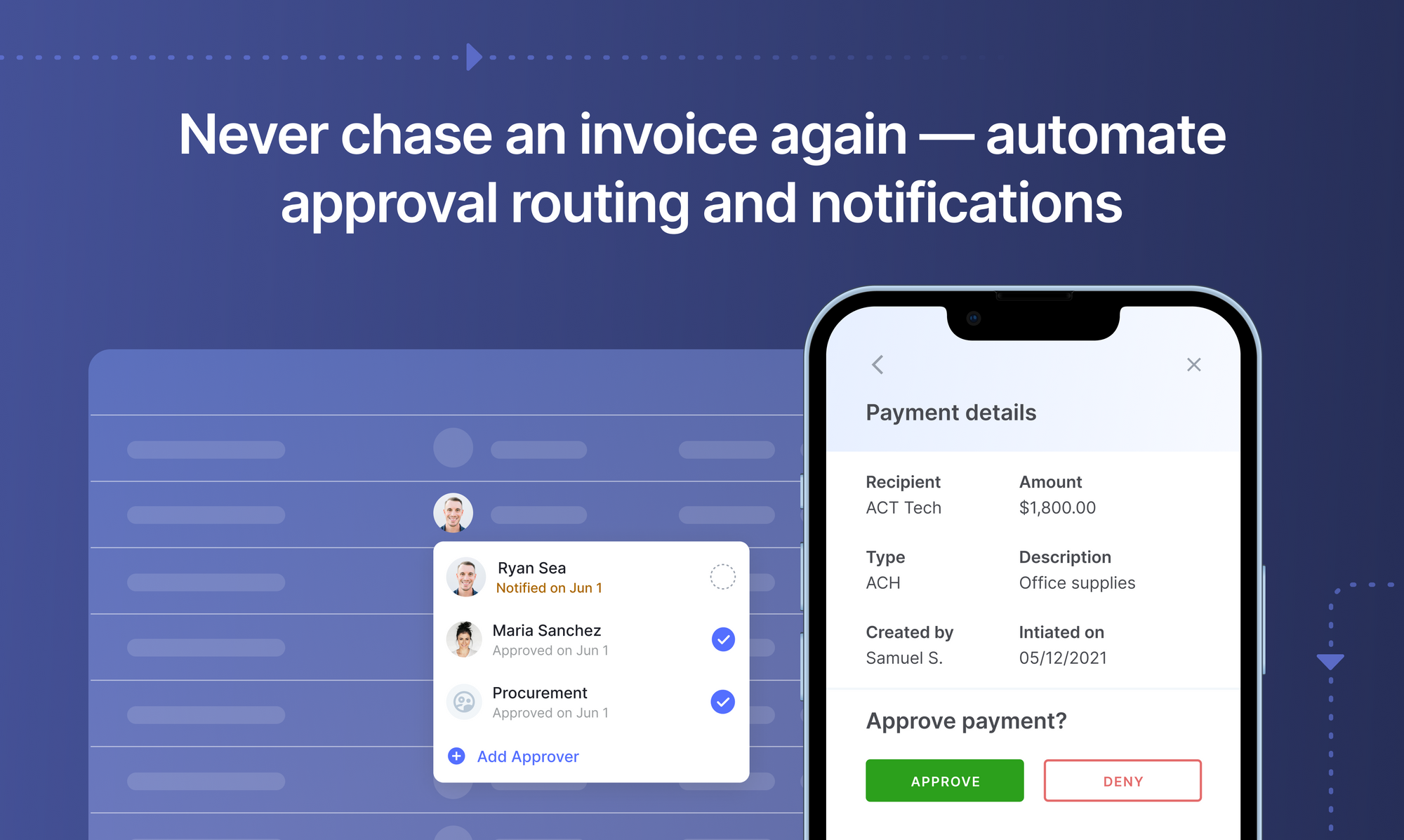

- Time savings: The use of digital tools to store, analyse and retrieve data helps in faster and error-free operations compared to manual processes. A 2018 survey of over 280 companies found that managers spend at least 8 hours a week on average in manual data tasks and 25 percent of all workers spend 20 hours a week on mundane data management tasks. With digitization, the stakeholders can receive their required product/services on time and need not waste time chasing orders through the process hierarchy. Digitization can also eliminate the practice of maverick purchasing.

- Cost savings: Automation of the procurement management process can help track the needs of various units of the company, follow up on the inventory, and optimize the PO-Invoice-Receipt process so that delays are avoided, which in turn can eliminate late payment charges and maintain better relationships with vendors. This can in turn translate to discounts and deals from the vendor.

- Analysis of data: The data that is stored in the digital domain can help optimize inventory levels and allow analytics, both of which can improve efficiency. For example, digitization and AI tools can help timely detection of demand for a product/service and induce proactive responses from the participants. Currently, 30% of retailers and manufacturers find forecasting future needs to be their biggest challenge.

- Transparency: Automation of the procurement process improves transparency in inventory levels, pricing, and supplier relationships. It can also enhance compliance to company/external policies and mitigate supply chain risks, corporate risks, and fraud.

How to digitize the procurement process

While digital tools are extensively available for the transactional purchasing activity – the use of software across the entire procurement cycle is gradually gaining importance. A comprehensive software that handles all aspects of the procurement process can accelerate savings from the enterprise spend. It can also enable seamless collaboration with all stakeholders and provide a complete database of information for planning purposes.

The automation of the procurement process requires meticulous planning in order to derive maximum benefit from it. The planning could include some or all of the following activities:

- Mapping of the existing procurement workflow in order to understand the modus operandi of the organization and the needs of the stakeholders involved in the process. Processes such as Business Process Modeling Notation (BPMN) could be used to visually represent the steps of the workflow. Building a procurement workflow will help in seamless transition into automation and prevent loss of time in adjusting to the new workflow.

- A careful audit of the existing procurement process would help identify bottlenecks that exist. This is important to know in order to know the features required of the software.

- Choosing the procurement software that best fits the needs of the company. The data storage location could be on-prem, centralized or cloud-based, depending on the specific needs of the company.

- Continuous assessment: Even after installation and running procurement automation tools, constant appraisals of the software’s performance would help optimize the system and avoid errors.

The digitization of the procurement process could involve a simple software that automates the transactional process or may include high impact technologies like ML and AI for the entire strategic process. The choice of the digital tool for the procurement process must be made based on the following factors:

- Budget: The scale of the business, the bottom line and the investment potential of the company are major drivers of the kinds of digitization/automation tools to be employed for procurement management.

- Ease of use: It must be remembered that training and set-up expenses are the biggest blocks to implementing any kind of automation in a process workflow. The skill level of the employees using the software will decide how user-friendly the front end of the software should be, and the level of tech support that will be provided by the developer.

- Need-tool match: It is important to check for a match between the company’s procurement process needs and the features provided by the tool, such as digital form creation, complex routing, and online approvals.

- Collaborative operation: This again depends on the scale of the company. If multiple departments are involved in the procurement of products/services, all stakeholders must have access to the process flow. Such an operation also requires provision to include various levels of approvals in the procurement process.

- Integration with the other systems used in the company: The software must integrate with the other systems such as accounting management tools used already in the company. Standalone sourcing-procurement software that does not integrate with the digital tools used in accounting and marketing departments would lead to data mismanagement and time loss.

Conclusion

Procurement is a strategic function of any organization and has wide-ranging business impacts. An efficient digital procurement process can seamlessly integrate the strategic process of procurement with the transactional purchase activity.

Automated procurement management is key to remaining competitive in the business world. Digital tools like Nanonets can help companies ease into automation, and thus enable them to focus on their core competencies and improve bottom lines.